Have any questions?

+44 1234 567 890

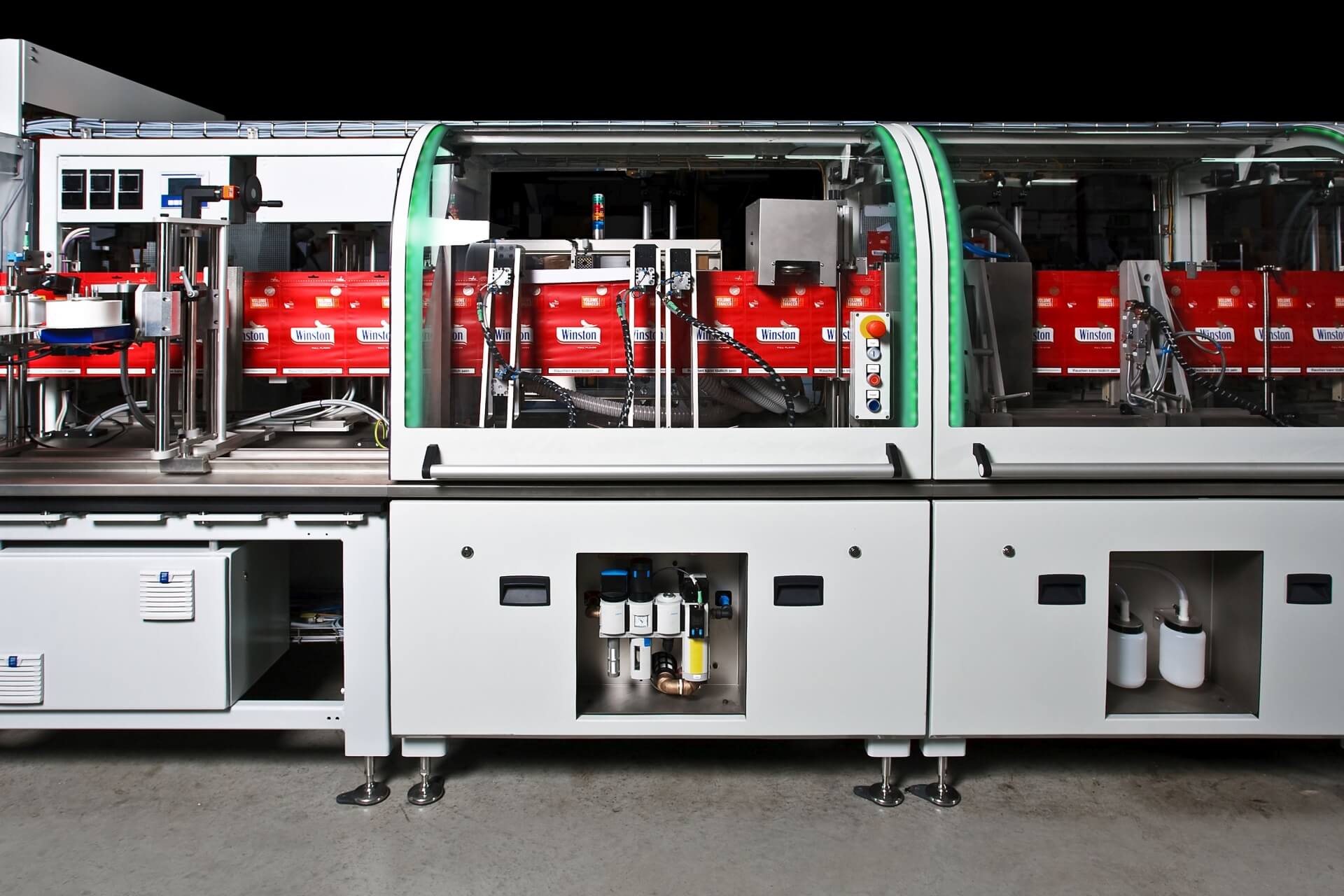

emkon. FLEXBAG

CASE STUDY: FLEXBAG JTI

CUSTOMER:

JTI - Japan Tobacco International

PRODUCT:

Tobacco in a stand-up pouch

CUSTOMER SINCE

2013

CUSTOMER REQUIREMENT:

- Improved product quality

- Higher production reliability

- Faster execution of format changes

- Simplified operating concept

- Lower overall operating costs

emkon. SOLUTION:

The emkon. FLEXBAG makes high-quality stand-up pouches in different sizes. With quick format changes, simple operating concepts and with the always-possible expandability, we achieve the highest degree of flexibility.

The consistent use of servo technology, the technical maturity and the reproducibility of all settings guarantees the highest degree of reliability and the desired quality during the production, transport, supply and sealing of the pouches.

FACTS:

| Machine data | |

|---|---|

| Output | Up to 100 cycles / minute |

| Simplex: 100 pouches / minute | |

| Duplex: 200 pouches / minute | |

| Triplex: 300 pouches / minute | |

| Quadruple: 400 pouches / minute | |

| Drives | Bosch Rexroth servo motors |

| PLC | Siemens S7 |

| Dimensions (l x w x h) | 11610 x 2630 x 2000 mm |

| Weight | 10700 kg |

| Product data | |

|---|---|

| Pouch dimensions | 50 x 50 mm – 400 x 400 mm |

THE emkon. FLEXBAG IN THE VIDEO

INTERVIEW:

BENEFITS:

Future-proof

- Extremely simple, quick and cost-effective adaption of machine to new products

- Modularity makes the adding of additional functions, or the installation of modified, newer technologies possible at any time (even after purchase)

- The modular design ensures a layout with optimal space utilization in every expansion stage

- Small investment steps through various optimal extension stages

- Basic, premium or various intermediate steps – the emkon. FLEXBAG is variable usable and adaptable at any time in the future

Reliable

- Intelligently responding to faults / delays of upstream und downstream machines (advanced driving profile with situational adaption)

- Fully automatic correction of supplier related material variations

- Fully automatic web guiding system

- Consistent use of servo technology

- Quick and easy format changes, reproducible at any time, nearly tool-free

- High standard of quality assurance

Simple, well-designed operating concept

- Interactive operator guidance system: Quick and easy fault detection through light signals reduces downtimes

- Robust and well thought out overall design

- Clean design, good accessibility

- Operation from one side only

- Reproducible settings via software

- "LED Guidance System" to assist the operator during production

Attractive overall cost

- High efficiency per square meter by the ideal layout and high output

- Minimum downtime through intelligent adaption to production influences

- Flexibility: simple, quick and cost-effective adaption due to standardized technology (lower follow-up cost for product innovation / modification)

- Use of low-wear parts to reduce service / maintenance costs

- Low energy and operating costs (Total Cost of Ownership)

Industry-specific features

- Very easily cleanable stainless steel design

- Consideration of Ex-protection guidelines (ATEX)

Special option: intelligent machine

- Intelligent, self-learning system

- Efficiency-enhancement through "self-optimizing" machine

Additional CASE STUDIES

emkon.

SMARTFOLD

emkon.

BISCUIT DEPOSITOR

emkon.

SURROUNDER

emkon.

MULTIPACK